Dispelling common cladding misconceptions

ThermoWood and Siberian Larch cladding on a seaside town renovation project, supplied by Silva Timber (image: Matt Rowe).

ThermoWood and Siberian Larch cladding on a seaside town renovation project, supplied by Silva Timber (image: Matt Rowe).

As a technical advisory service, the Timber Decking & Cladding Association (TDCA) receives enquiries daily. But too often we get asked the same fundamental questions. We’re working hard to address them by providing free resources on our website as well as on-hand guidance. We take a closer look at some common cladding queries…

What is external timber cladding?

What is external timber cladding?

Timber cladding is an arrangement of boards covering the exterior of a building. Not only does it add a design feature to a building, but it also provides extra protection against the elements.

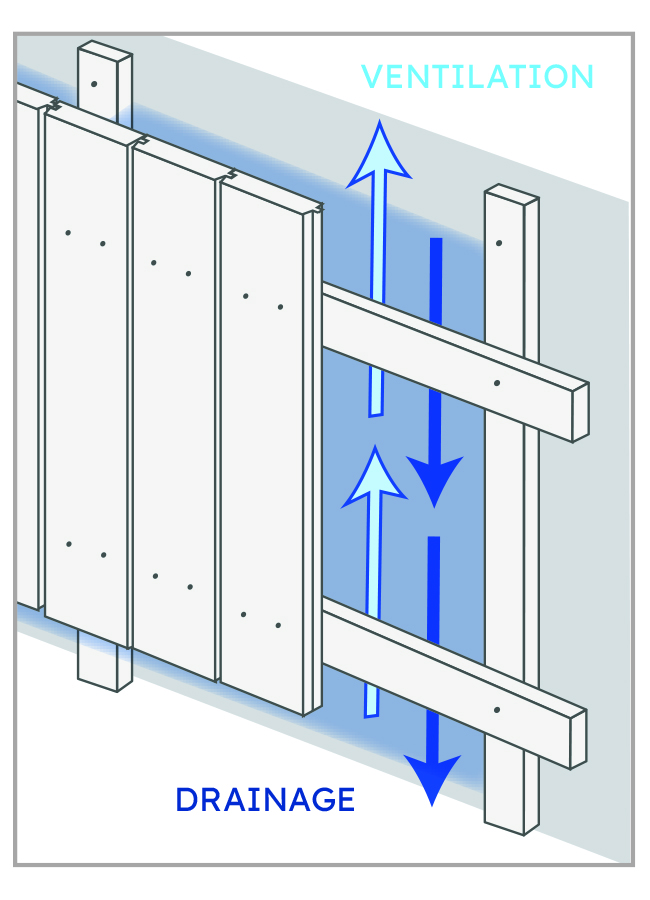

In UK conditions timber cladding on occupied buildings should be designed as a rainscreen – meaning it is fitted over a drained and ventilated cavity. The cavity is created by the battens on which the cladding boards are fixed.

Material selection, design and installation techniques are key to ensuring an effective and well performing application. Timber is a natural material, as such its natural movement must be accommodated within the cladding design. It must also be detailed to avoid moisture traps to facilitate drying following periods of wet weather.

What options do I have in terms of timber materials and profiles?

IRO Timber cladding (Charcoal) from BSW Timber

The timbers used to manufacture cladding boards are specifically selected for their appearance, durability and suitability for use in an above ground outdoor environment (Use Class 3). This includes pressure treated softwoods, naturally durable softwoods like western red cedar, naturally durable hardwoods such as Cumaru and modified wood brands including Accoya and Abodo. Coloured and textured factory finished products are also on the market. Depending on your product choice, desired services lives can range from 15 to 30 to 60 years.

Profile styles are varied and include close jointed styles such as tongue and groove, shiplap and featheredge, rectangular for board-on-board arrangement and parallelogram for open jointed designs. Suitability for vertical, horizontal or diagonal arrangement is dictated by the profile style. For example board on board is only recommended for vertical arrangement and parallelogram for horizontal.

Whatever you choose, be certain it’s appropriately dried to a moisture content of 16%+/- 4% when installing. Employ the services of a reputable and experience installer: CladMark accredited installers are audited annually by the TDCA to ensure they have the capability and knowledge to work with timber cladding successfully.

Does the size of the profile matter?

Guidance on profile dimensions is given in British Standard 8605 – External Timber Cladding part 1: Method of specifying. For all profile styles, the standard recommends a board width-to-thickness ratio of between 4:1 and 6:1. Cladding manufacturers should ideally adhere to these recommendations. It’s possible to go higher that the x6 ratio but only with timber species classed as ‘very small movement’ (e.g Accoya) and lower than x4 if the additional material and installation costs incurred are acceptable. Further board characteristics and dimensions, such as movement gaps and overlaps are also detailed to ensure profiles are designed for a trouble-free installation.

What kind of battens should I use?

The preferred batten material is softwood, usually pine, pressure treated with a wood preservative to a Use Class 3 specification – making them suitable for external use above ground. With timber cladding not all wind driven rain is deflected and moisture gets into the cavity.

Roofing battens are not suitable as these are treated to a lower use class 2 specification as they rarely get wet.

To accommodate the board fixings, batten dimensions should be at least 50 x 38mm, vertical counter battens, necessary where cladding boards are arranged horizontally, can be 50 x 25mm.

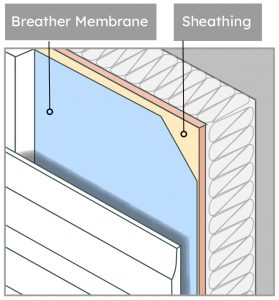

Is it necessary to use a breather membrane?

As described, the cladding assembly should be designed and constructed as a rainscreen meaning the external timber cladding should be separated from the exterior insulation (or backing wall) by a drained and ventilated cavity. Some water will always penetrate the cavity and so the rear face of the cavity needs to be designed as a secondary drainage plane. This plane is usually termed a ‘breather layer’ in the UK and is constructed using a breather membrane or equivalent moisture resistant, but vapour open material, protecting against wet weather penetration whilst allowing moisture from behind it to escape.

There are some instances where a breather membrane may not necessary. Where a masonry construction (stone, brick, breeze block, etc) has been specified and constructed for external conditions, no additional weather protection is needed – presuming the surface is sound, with a rendered finish or coated with a water repellent. If, however, the surface is loose (e.g. an old stone wall) then a breather membrane is an economical way of providing a drainage plane. The membrane can be held in position by the cavity battens.

Where open jointed cladding is concerned, a membrane is advisable.

What’s the word on fixings?

Where problems occur with external timber cladding, fixing faults are often the culprit. The TDCA regularly sees errors relating to fixings type, placement, and application – but such mistakes are easily avoided. The use of corrosion resistant fixings suitable for outdoor use and specific to exterior timber cladding, are a must. Here are a few more pointers to help.

- For most softwoods, ring shank nails are the order of the day – although screws have the advantage of allowing easier removal if necessary.

- On hardwoods and higher density softwoods, screws are more appropriate

- Through fix at every batten intersection placing the fixings at quarter points of the board and at least 20mm in from board ends.

- Take care with nail guns to avoid damage to the board surface.

- To determine the length of fixing required the TDCA has a simplified calculation: for nails it’s total board thickness + 24mm and screws, total board thickness + 29mm.

Where can I find out more?

The Timber Decking and Cladding Association (TDCA) is a not-for-profit, independent trade organisation – proud to be considered a much-respected voice in the industry. TDCA promotes best practice and provides technical advice – in the form of publications, email enquiries and by telephone too.

If you would like to know more, head over to the TDCA website which is packed with useful information about timber cladding and timber decking too. Illustrative guidance in the form of The Timber Cladding Handbook can be downloaded free of charge to registered users.

Do you need advice about a timber decking or cladding project? The TDCA is there to help you – the DIYer, the landscaper, the architect, the specifier and the contractor.